Advanced Control Capability for Microgrids and DER

Microgrids will become “essential building blocks of the future electricity delivery system to support resilience, decarbonization, and affordability.” The U.S. Dept. of Energy envisions this fully materializing by 2035. Nhu Energy is helping to make this a reality providing advanced digital intelligence on one-of-kind and ground-breaking microgrid projects in commercial-industrial and utility applications.

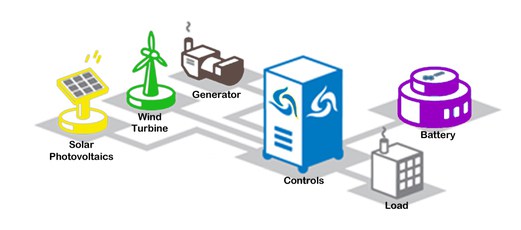

Microgrid Plant Controller

Nhu Energy’s microgrid plant controller provides a full spectrum of capabilities and integrates with a number of major microgrid power electronic converter and energy storage technologies.

- SCADA – analog, discrete, and digital I/O processing, management

- Startup, shutdown – manual and automatic

- State management – modes, permissives, interlocks, protection

- Stable operation of the plant in various modes

- Support for multiple control modes

- Support for multiple architectures (AC-coupled, DC-coupled, reverse DC-coupled)

- Support for intentional and automatic/unintentional islanding

- Support for “blinkless” transfer, uninterrupted power to load

- Support for manual and automatic reconnection / resynchronization

Predictive Optimal Control

Our patented predictive optimal control algorithm, Discretized Optimal Control Technology for Distributed Energy Resources (DOCTDER), performs cost-minimization constrained optimization to decide the best way to dispatch controllable DER resources such as energy storage based on predictions of variable resource generation (such as solar PV), load, and grid price. This works in concert with the Nhu Energy Microgrid Plant Controller, delivering additional value through digital control and optimization through utilization of predictions, a.k.a., forecasts, which can be generated locally or sourced from external forecasting services.

- Predictive multivariable cost-optimal control

- Flexible- can incorporate different constraints and objectives

Forecasting / Prediction

The most effective use of energy storage, the most costly resource in a microgrid, comes when prediction is incorporated in the over digital control and optimization suite. To “store”, by definition, means to “keep for future use”, which requires control to be continuously making an assumption about the future. This is best accomplished by incorporating prediction in the control system.

- Local forecasting using historical and met station data

- Capability to import and use external forecasts

- Solar, load, and grid price

Visualization

A window into microgrid operations is necessary both for the operation, maintenance, and control of the plant, but, also for higher level analysis and reporting. Nhu Energy provides industrial-utility grade human-machine interfaces (HMI’s) for full-featured comprehensive monitoring and control, as well as our SunDial ™ web portal for analysis, trending, and reporting (mainly view-only and no control).

- Plant control HMI – real-time monitoring, control, trending, alarming

- Management and reporting

- web / cloud-based

Grid-Edge

As microgrids to become major building blocks of the future grid, they must be capable of integrating into electric grid operations and participating fully in electric utility and system operator programs and services. Nhu Energy’s suite of microgrid and DER control capabilities is developed with this in mind.

- ADR – OpenADR compliant interface for participation in utility DR programs

- VPP – coordinate control between microgrids

Case Study: Kaiser Richmond Microgrid

This was the first entirely renewable, solar plus storage, microgrid at a hospital in the U.S., and the first capable of power life safety systems with 100% clean energy. Nhu Energy partnered with Charge Bliss, Florida State University, the University of California at San Diego, Kaiser Permanente, and others, with funding from the California Energy Commission, to develop, de-risk, and deploy digital microgrid controls capabilities for this system. This project demonstrated comprehensive use of Controller Hardware-in-the-Loop (CHIL) simulation-based testing methods to thoroughly test and de-risk microgrid controller capabilities before deployment in the actual hospital microgrid. As a result, the microgrid supervisory controls worked properly from the very beginning.

Nhu Energy provides our Operating Technology as a Service (OTaasS) ™ support for this system, which has been delivering significant demand charge savings continuously for Kaiser Permanente for many years, since the microgrid went into commercial operation in 2018.

Contact us for additional case studies on cutting-edge applications of microgrids, including the first long-duration energy storage microgrid at a hospital and the first solar+storage only utility distribution circuit microgrid.